Design. Develop. Deliver.

Founded in 1998 as a product design consultancy, design has always been at the core of what we do. We’ve spent over two decades helping clients turn ideas into well-resolved, production-ready products — combining creativity with deep practical understanding.

Our design process is grounded in clear thinking and real-world constraints. We begin with research and concept development, then move through detailed design refinement, CAD modeling, and 3D printing — which we use extensively for prototyping and design communication. This allows us to test form, fit, and function early in the process, reducing development risks and improving clarity for all stakeholders.

As the business evolved, we expanded into injection Mould tooling, plastic part manufacturing, and — more recently — direct-to-object printing, which we introduced eight years ago. This lets us print high-quality graphics, branding, and functional markings directly onto plastic parts and enclosures, streamlining production while enhancing the finished product.

Today, our design offering is seamlessly integrated with manufacturing. Whether you’re starting from scratch or refining a design for production, we bring a practical, end-to-end approach that ensures your product is ready for the real world — inside and out.

We turn ideas into real-world products.

With a unique blend of creativity and technical know-how, we bridge the gap between design and production — delivering practical, reliable results every step of the way.

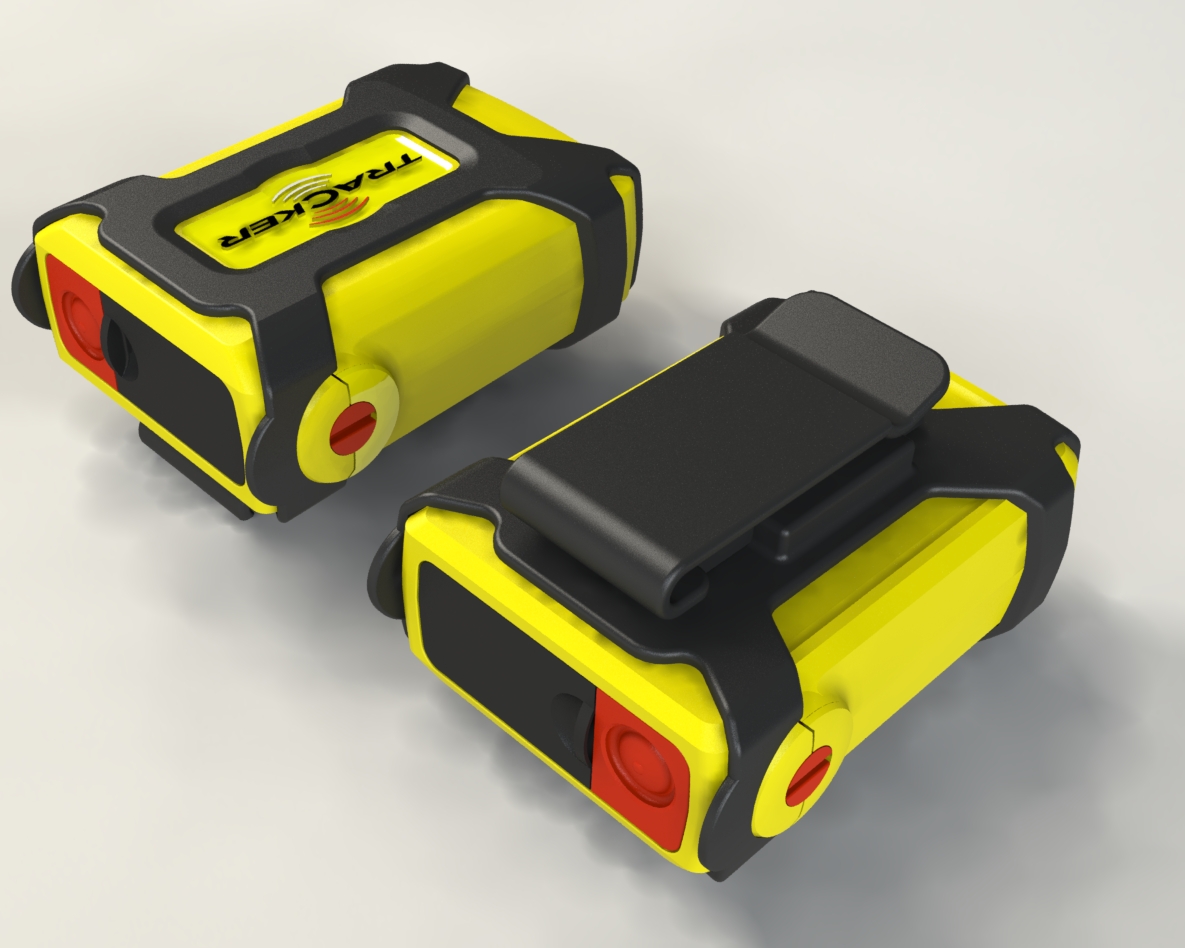

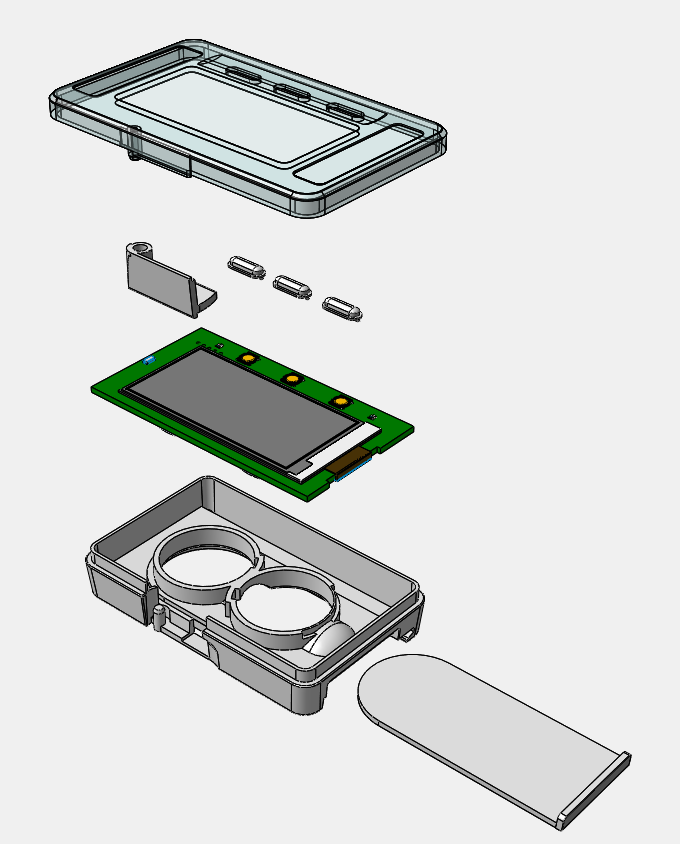

Children Safety Device – Exploded view

Children Safety Device – Exploded view Children Safety Device

Children Safety Device

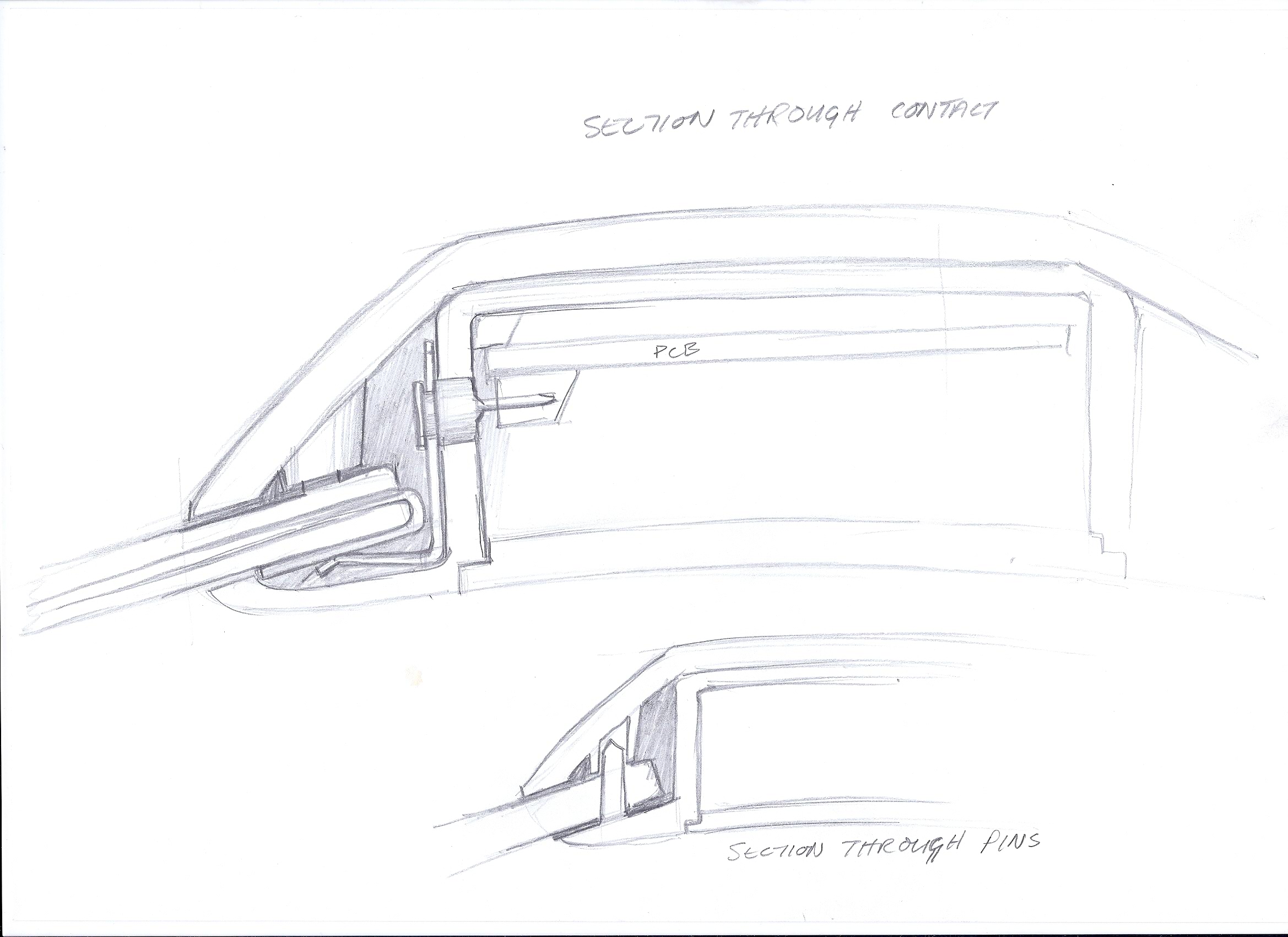

Antenna Housing and Bracket

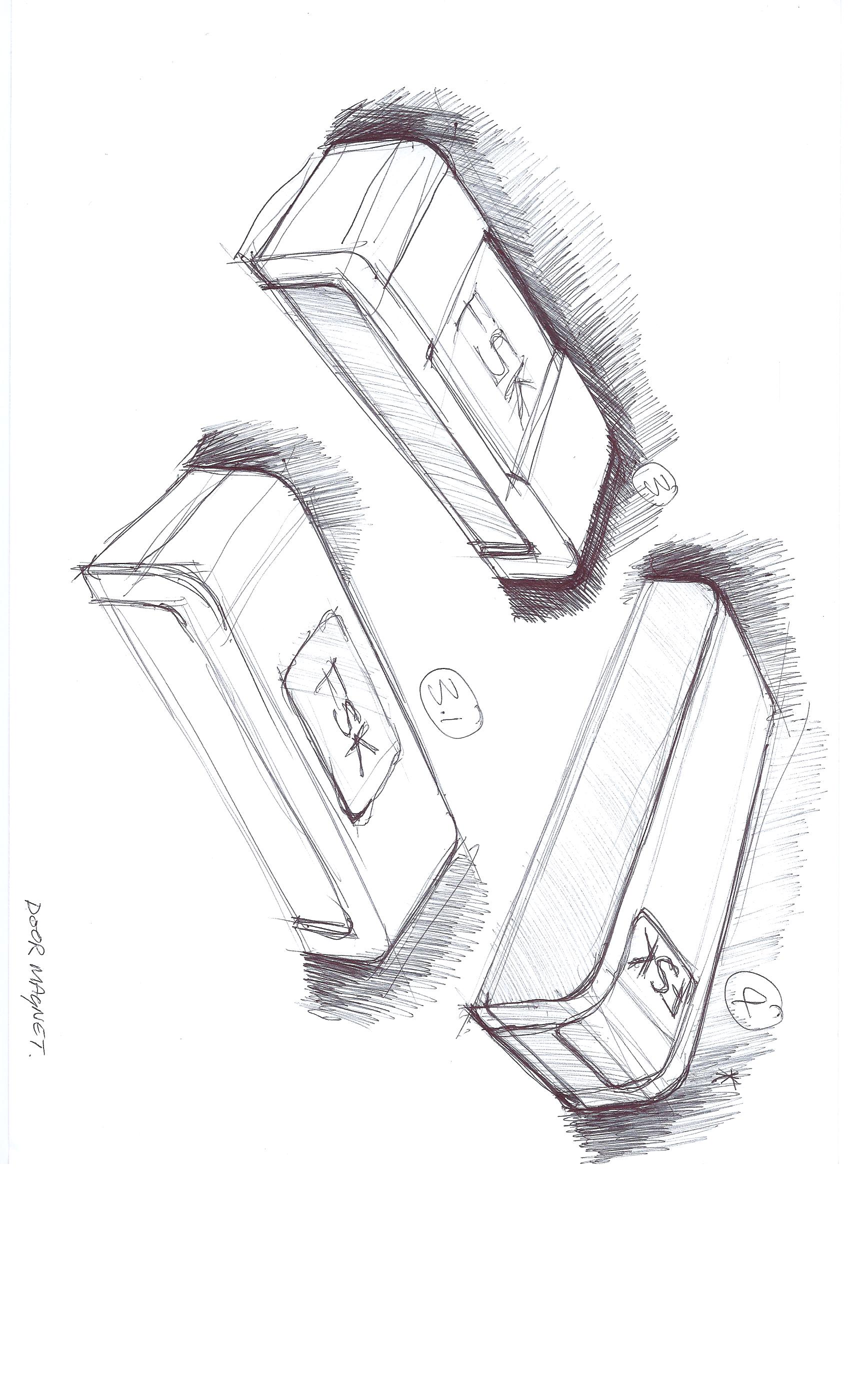

Antenna Housing and Bracket Printed Enclosure

Printed Enclosure